Forma electronica erroris

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

News

How to Maintain the Die-Casting Mold

The quality, cost, and total amount of the product are all related to the quality of the injection mold and the timeliness of the maintenance. Therefore, the maintenance method of injection mold is especially important, and we will introduce several types of skills for you.

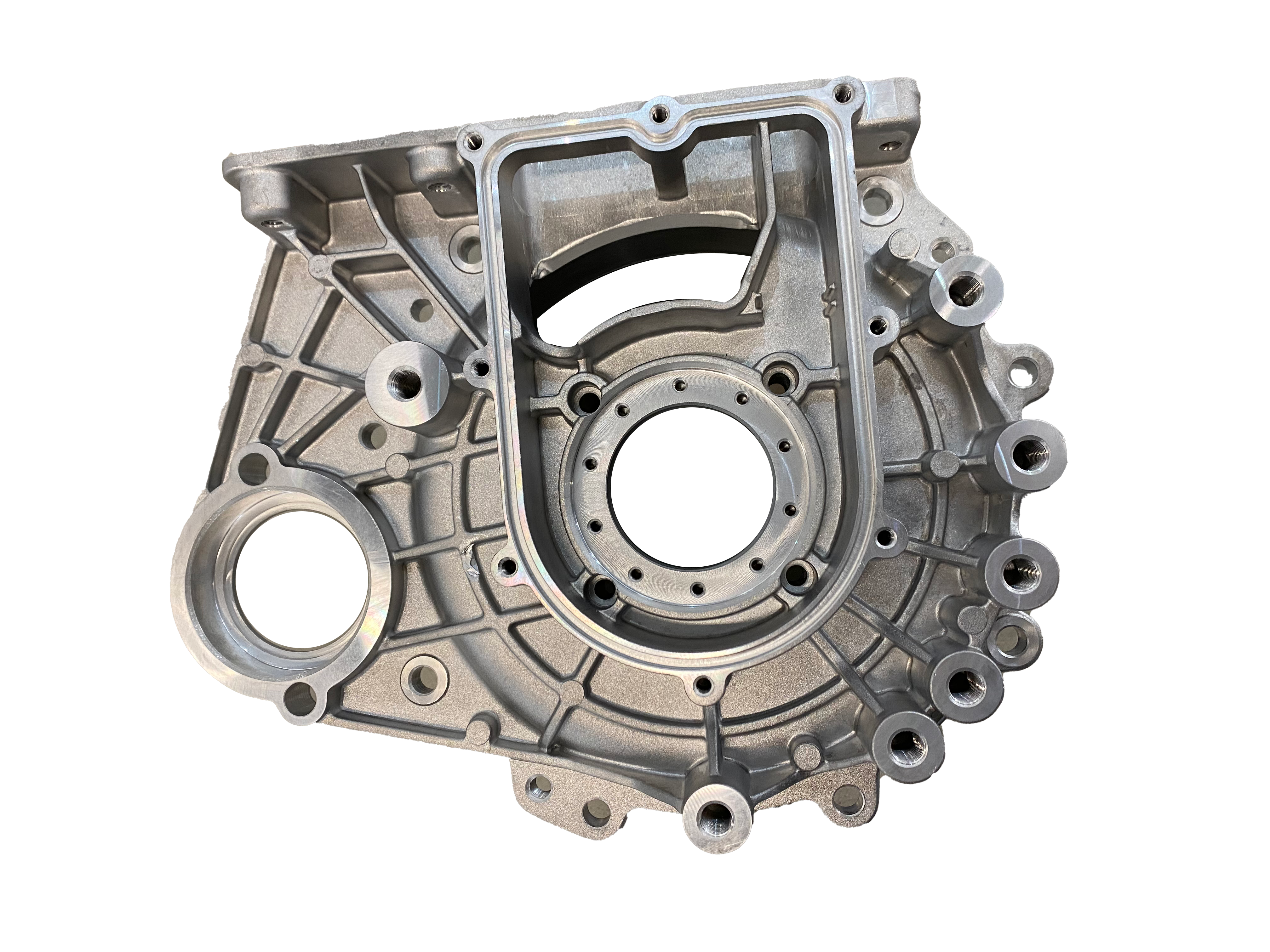

Common casting molds

- Forging forming die: forging and casting, like, are the production of zero, parts of the most commonly used processing technology, forging die are mainly: die forging and large press with forging die, screw press with forging die, flat forging machine forging die, roll forging die, etc., at the same time, fasteners cold heading die, extrusion die, drawing die, liquid forging with die, etc. are also equally belonged to forging die.

- Stamping die: also known as punching die, stamping die in the cold stamping process, the material will be processed to get the parts of the process equipment. This type of die mainly includes punching die, bending die, drawing die, single process die, compound punching die, progressive punching die, as well as automobile covering parts punching die, combination punching die, motor silicon steel sheet punching die.

- Plastic forming mold: Due to the wide application of plastic in life, plastic forming is also a very common processing material in the industrial field. So in order to process plastic, in the mold, there are plastic molding molds: compression molding molds, extrusion molding molds, injection molds, thermosetting plastic injection molds, extrusion molding molds foam molding molds, low tooling tool bubble injection molding molds and blow molding molds are all plastic molding molds.

- Casting with metal mold: this type of mold and die-casting mold has some similarities, but it is more focused on casting, a variety of metal parts used in the casting of metal models.

What are the maintenance methods of die-casting molds?

Choose well type of vapor carburizing furnace heating

Some specifications are too long, and not quite suitable for other tempering treatment methods. Can be considered to this method to carry out tempering treatment, only must be placed on the bottom of the clamp pot slightly fixed immobile vertical heating can be. Temperature control must be done at 800 ℃, in order to be able to carry out antioxidation and carburization maintenance of the parts of the grinding tool. The same, can use the electric furnace in the furnace method, can improve efficiency, and reduce the mold parts heating time.

The use of stainless steel plate film paper

Stainless steel plate outer film paper is slim stainless steel plate foil, its thin thickness is 0.03 ~ 0.11mm. thin, and mountain stone-like can be retracted, good sealing characteristics, heat-resistant. Only the parts of the abrasive tool must be held up with the outer film paper and put into the heat treatment equipment sub immediately. However, the outer film paper will become more and more unapplicable in the natural environment of tempering treatment, and it is also easy to break. To put it simply, it is not easy to remove, so a special type of tin can be made for easy removal. However, there is also a technical problem, that is, the packaging of the outer film paper is very technical, and more serious harm to the quality of antioxidation, anti-carburization.

Application of anti-reduction agent

Anti-reduction agent in the case of heating will produce an extra-thin protective film on the mold parts, in the mold parts heat treatment refrigeration, quenching, quenching announced the whole process will fall off independently, not easy to endanger the cooling of mold parts, and will not cause harm to the heat treatment substances.

For the size of mold parts, large and small mold parts are more suitable brush coating method, small and medium-sized mold parts with invasion can be

Special attention is paid to the anti-reduction agent mainly to try to avoid the air oxidation of parts, carburization, can not completely remove the air oxidation of parts, carburization. If the parts or grinding tool process performance provisions of high, parts or grinding tool to stay very small capacity can not choose the way anti-reducing agent maintenance, such as Cr12MoV raw material grinding tool.

Conclusion

For more information about types of the die casting process,intensification pressure in die casting,pdc die casting machine, we are glad to answer for you.