Forma electronica erroris

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

News

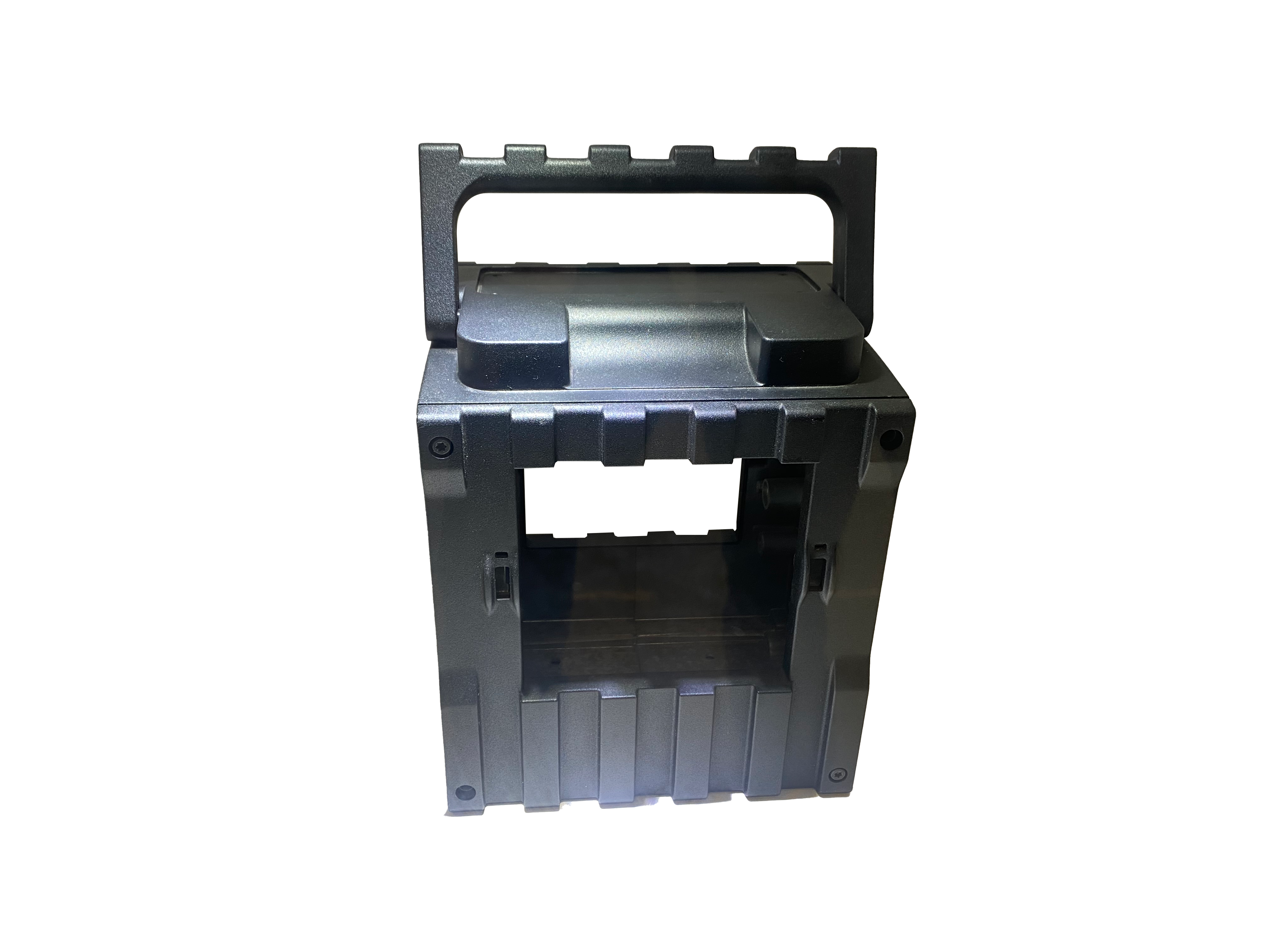

How to Deal With the Poor Plating of Die Casting

Zinc alloy die-casting the whole process of the greater depletion of the stage must be attributed to the metal surface treatment, in which and electroplating process processing method is greater, then how to deal with this poor plating process goods?

Common problems about Zinc alloy die casting plating process: back plating

Zinc-aluminum alloy die-casting is──a kind of aluminum die-casting parts with zinc as the main component. These parts have a high-density surface, and the inside is a firefighting sparse porous material, but also a cheerful amphoteric metal. Therefore, only the choice of moderate former solution and plating can ensure that the plating process layer on the zinc alloy material has excellent adhesion and achieve the provisions of qualified products.

The common raw material of zinc alloy material for electroplating process is ZA4-1, whose main components are: aluminum 3.5% to 4.5%, copper 0.75% to 1.25%, magnesium 0.03% to 0.08%, capacity of zinc, total residue ≤ 0.2%. And 925 models of zinc alloy materials with high copper content, but also to facilitate the plating process. In general, the relative density of zinc alloy material is 6.4 ~ 6.3g/cm, if the relative density is <6.4g/cm, the electroplating process is easy to produce bubbles and black spots. In a word, try to strictly supervise when selecting materials. In addition, aluminum die-casting when the abrasive tool must be designed program effective, to prevent the plating process to produce insurmountable shortcomings (such as black spots).

Zinc alloy die-casting process characteristics

- zinc alloy die-casting process manufactured by the product ratio is relatively much larger, and it also has a better texture and more weight, the strength of this process is much greater than the strength of plastic injection molding.

- zinc alloy die-casting process its casting performance is super good, in addition, this processing method can manufacture at the traditional process can not be manufactured out of more complex and very thin wall products, and the surface of this product is very smooth, not rough.

- using the zinc alloy die-casting process out of the mold it can also be re-surface processing, can be in the surface of electroplating, painting, and other processing.

- using the zinc alloy die-casting process to manufacture molds, its production efficiency is very high, and the service life of the mold is much longer, up to able to use up to 10,000 times of die-casting.

- zinc alloy die-casting process has a very good product manufacturing effect, using this technology to produce products has very good room temperature mechanical properties, that is, in the long time use will not appear high temperature, in addition, it also has very good wear resistance, will not easily wear.

- using the zinc alloy die-casting process produced by the product melting point is relatively low, at about 385 degrees Celsius can melt the product, so this product can be better production molding.

- the main point is that the price of the mold produced by the zinc alloy die-casting process is much lower than the price of the mold produced by the traditional process, which greatly saves a large number of production costs. This is the most important point for every user.

Conclusion

Zinc alloy die-casting process in the current market listing most of the mold manufacturers use a mold production technology, the use of this constraint produced by the product either in terms of quality or in terms of price is far better than the other products are much better. It is also the product that users prefer now.

For more information about ejector pins in die casting,zinc die casting components,die casting machine tonnage calculation, we are glad to answer for you.